What do our clients say?...

..."There is a definite reduced operation time of the crane..."

..."The crane often had to wait until an operator travelled to the load to release the hook. Now the crane does not stand still, and there's no downtime..."

..."Murphy’s Law is true. You are at the top of the bulding and the concrete skip or the pallet fork is at the bottom… With HENEN ANJUN, this is no longer a problem…"

Safety Benefits:

1.No need to be near the load or the crane boom

2.Avoid injuries or chronic illness as it is not necessary to repeatedly climb up and down the truck bed.

3.The HENAN ANJUN automatic hook is fail-safe. It is not possible to drop the load while suspended.

1.Tower Cranes

HENAN ANJUN tower crane is a lifting equipment used in the construction of high-rise buildings. They are often used on construction sites, and they are capable of easily lifting and lowering loads thanks to their height. Tower cranes stand on a vertical tower and have a lifting boom to ensure that loads are transported. The lifting boom, by virtue of the height of crane, cover large distances and can usually rotate 360 degrees. Tower cranes are usually made of steel or aluminum. These materials increase the durability of cranes and ensure that they are resistant to wind and other natural influences that may occur by dint of the height of the cranes. Tower cranes are available in a variety of capacities and are usually selected based on the size of the construction site and load requirements. Tower cranes can be used for various purposes, such as handling materials in high-rise construction buildings, lifting heavy prefabricated components, assembling reinforced concrete walls, floors, and beams. The advantages of tower cranes include a large coverage area thanks to its height, large load capacity and fast load lifting operations.

HENAN ANJUN tower crane matches remote hook increases the safety of crane loading operations by preventing the operator having to manipulate the hook and load. There is also the possibility of installing the remote control inside the crane.

2.Fold of the Crane

2.Fold of the Crane

Depending on the model and size of crane, it is advisable to do some work for installation, so that the automatic hook is properly stored and does not exceed the gauge. It is a simple customisation.

3.Container Spreader

3.Container Spreader

The Container Spreader can tilt a fully loaded container on a single hook, creating a mobile method for tilting loaded containers. The self-contained unit can be remote-controlled and contains a built-in power pack, so no power source is needed. The tilt is controlled and safe, with a built-in center of gravity adjustment, and can be used with virtually any crane.

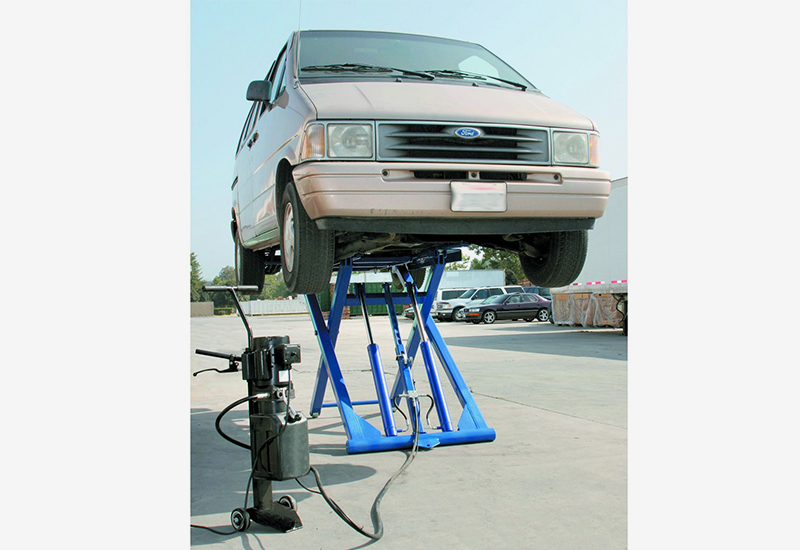

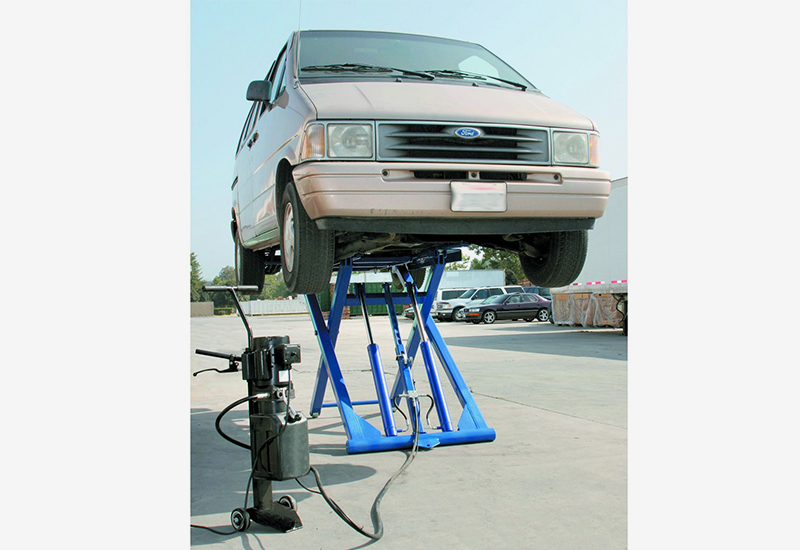

4.Mobile Lift Platform

4.Mobile Lift Platform

HENAN ANJUN provide scissor aerial work platform provides automatic walking,vertical lift and platform extension function.suitable for indoor and outdoor environment,widely used in electric power,petrochemical.manufacturing equipment installation and maintenance.

Performance characteristics

Operators can drive, steer and lift directly on the platform to achieve continuous operation when there is only one person, no need to hâve any control from the ground.

The châssis is equipped with drawer electrical box, which can easily access parts and facilitate maintenance.

The SC05/06(E) sériés is very compact in size and suitable for operation in confinsed spaces such as elevators.

The platform and châssis are equipped with automatic fault code display to facilitate maintenance.

HENAN ANJUN also provide scissor car lifts, double-deck scissor car lifts, four post car lifts and turnable car lifts with standard and custom designs. Widely used for car storage, parking and display in home garage, basement, 4S store, etc.

5.Transporting Girder Vehicle

5.Transporting Girder Vehicle

HENAN ANJUN provide transporting Girder Vehicle are “mechanical- electrical hydraulic” products with high technical content. The complete vehicle uses hydraulic drive, hydraulic suspension , hydraulic lift, mechanical -electrical- hydraulic coordinat ion controlled mult i-axle steering system and implements the movement modes including st raight running, oblique running , splayedstee ring and half-sp layed steering, etc. The finished vehicle can be operated very maneuverably and flexibly, the functions of various systems can be controlled, coordinated and implemented through micro-electro system, thus to solve the problems of “differential force and differential speed” and “slipping” during the running, enabling each tyre to implement “pure rolling” movements and basically implement slippage -free or less -slippage running. The finished vehicle can implement the functions of “whole lifting and whole descending” and “single point lifting and descending” , meeting the precise alignment requirement of girder transporter during automatic leveling and girder feeding.