Replace OEM number

| HFU620CAS010JUW |

HFU640CAS010JUW |

HFU660CAS010JUW |

HFU620UY020H13 |

| HFU640UY045H13 |

HFU660UY400H13 |

HFU620GF100H13 |

HFU640GF200H13 |

| HFU660GF050H13 |

HFU620UY020J |

HFU640UY020J |

HFU660UY020J |

| HFU620UY045J |

HFU640UY045J |

HFU660UY045J |

HFU620GF100H13 |

| HFU640GF200H13 |

HFU660GF100H13 |

HFU620UY200J |

HFU640UY200J |

| HFU660UY200J |

HFU620UY400J |

HFU640UY400J |

HFU660UY400J |

| HFU620UY700J |

HFU640UY700J |

HFU660UY700J |

RFP010-40 |

| RFP050-40 |

RFP100-40 |

RFP500-40 |

HF40PP005 |

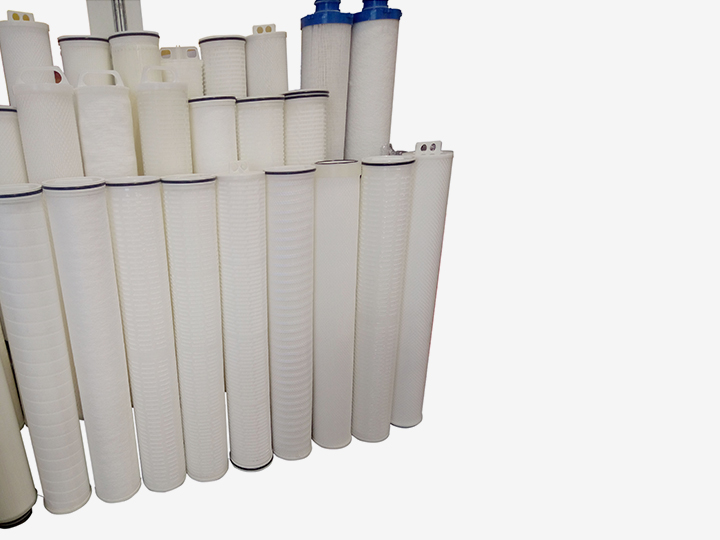

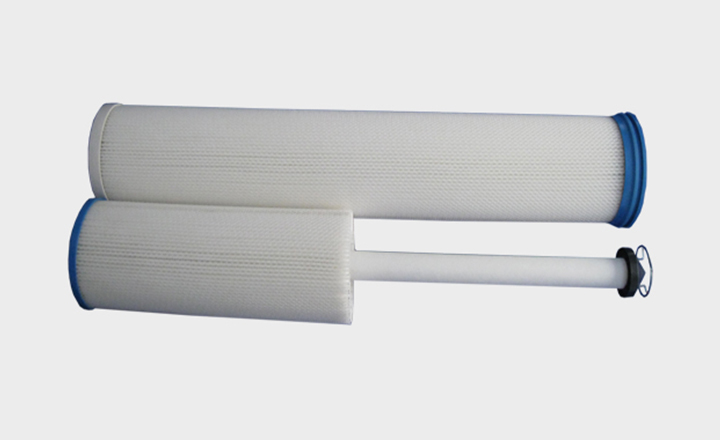

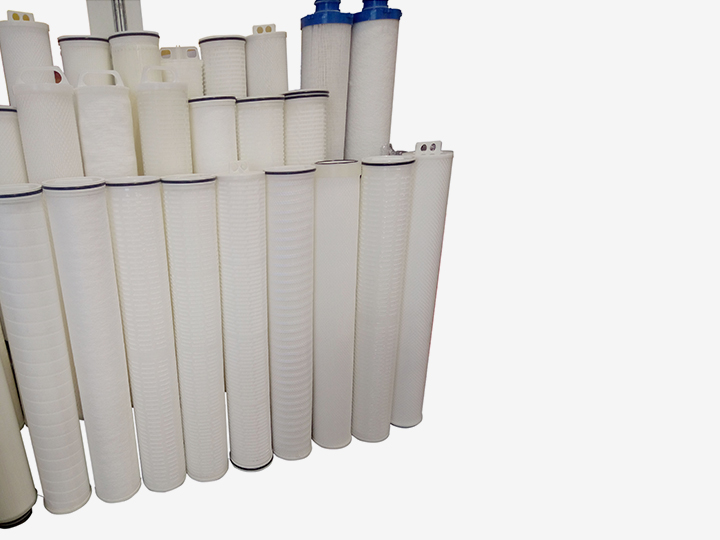

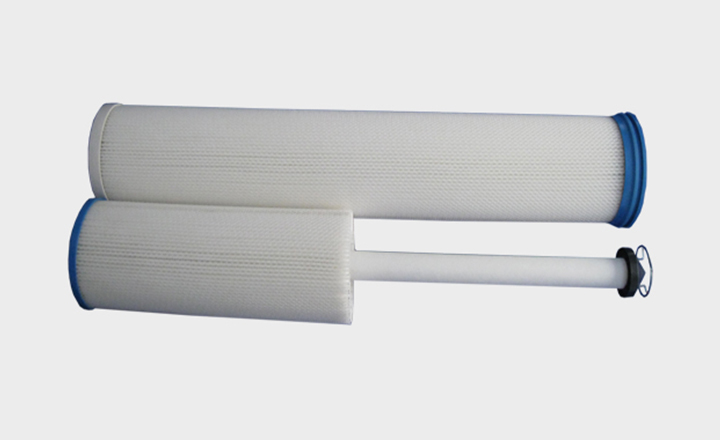

Production Description

High Flow Filter Cartridge is made of diameter 6 "(152mm), single open end, port size 180mm, without inner core, inside to outside flow direction. End caps and filter layer using hot-melt welding, no bonding agent, with a wide range of chemical compatibility, can be applied to various fields. It’s our new design, which can completely replace the filter bag.

Production Performance

| Outside Diameter |

152mm [6 in.] |

Length |

10" 20" 30" 40" 50" 60" 70" |

| Weight(20") |

2.3kg |

Removal Rating |

1~100μm |

| Filter Media |

Polypropylene pleated filber glass melt blown Polypropylene |

End Cap |

Reinforced PP |

| Seal Material |

Silicone EPDM NBR Viton |

Core |

PP |

| Maximum Operating Pressure |

3.4 Bar 80°C 1.03Bar 65°C 3.4Bar 120°C |

Maximum Operating Reverse Pressure |

2.0Bar 25°C |

| Suggested Maximum Flow Rate: |

20" 660L/M 40" 1300L/M 60" 1900L/M

|

| Maximum Operating Temperature |

3.4bar 80°C(pp pleated) 1.0bar 65°C (melt blown pleated) 3.4bar 120°C(fiberglass pleated) |

Features And Benefits

Outer cage is one piece, we are the only one in domestic.

Inside to outside flow direction keeps all of the contamination catched.

Gradient aperture deep polypropylene fiber filter media, aperture along the fluid motion direction becomes smaller, levels intercept different sizes particles, which has excellent dirt holding capacity and low flow resistance.

Application

Power Plant

Condensate polishing purpose:

1. To remove metal corrosion products

2. To remove trace dissolved salts in condensate water

3. To remove suspended solids

Pharmaceutical

Water treatment, liquid medicine

Desalination

Desalination or Desalinization, seawater pretreatment its purpose is to remove particles silt, colloids, microorganisms and other impurities present in the surface seawater, which ensure long-term stable operation of reverse osmosis system. Seawater pretreatment process design pretreated water quality should meet water quality requirements of reverse osmosis membrane elements. Setting the security filter in front of the reverse osmosis unit to protect the high-pressure pumps, energy recovery and safe long-term operation of membrane elements.

Water Pre-treatment

Water Pre-treatment is to remove the organic matter, suspended solids, colloids, chlorine and calcium and magnesium ions, so as to ensure that RO water requirements.

Oil and Chemical

Membrane separation is one of oil and chemicals wastewater treatment method, including reverse osmosis, nanofiltration, ultrafiltration and microfiltration, which can effectively remove organic matter ,various particles and microorganisms in wastewater, ensure effluent quality stable and reliable.

Food and Beverage

Wine, beverage, mineral water, dairy products, etc

Electronics

Prefiltration of pure water for Semiconductor chip, CD, display, optical products.